RoboBox

Technical data

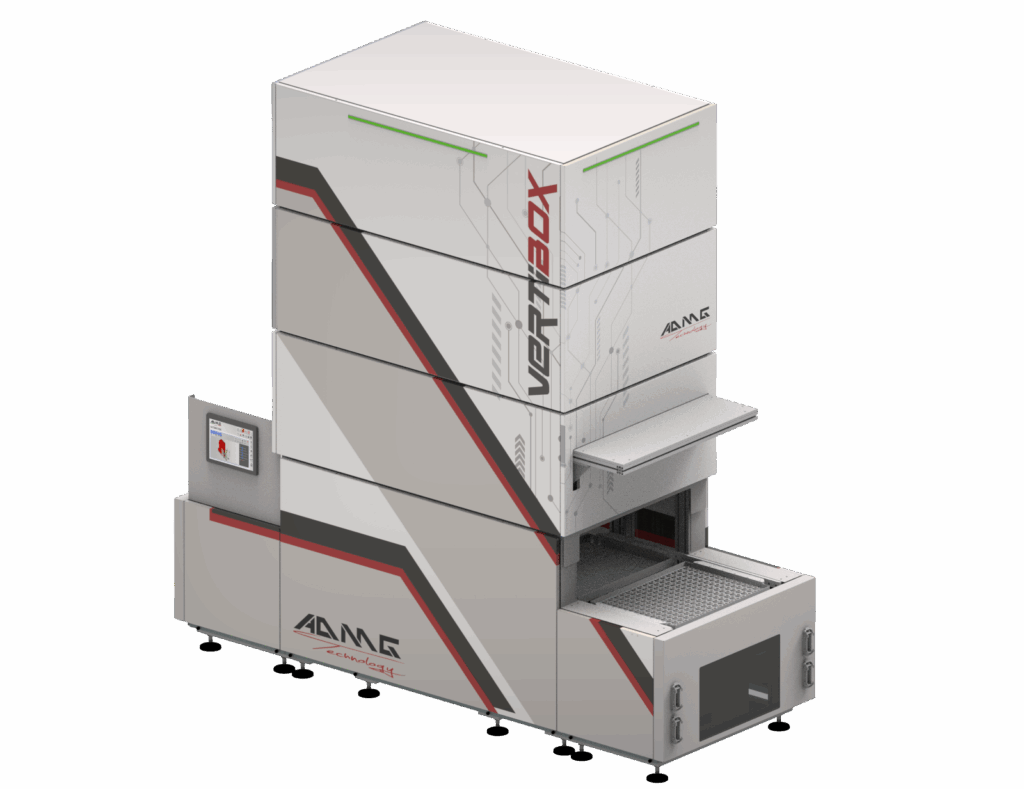

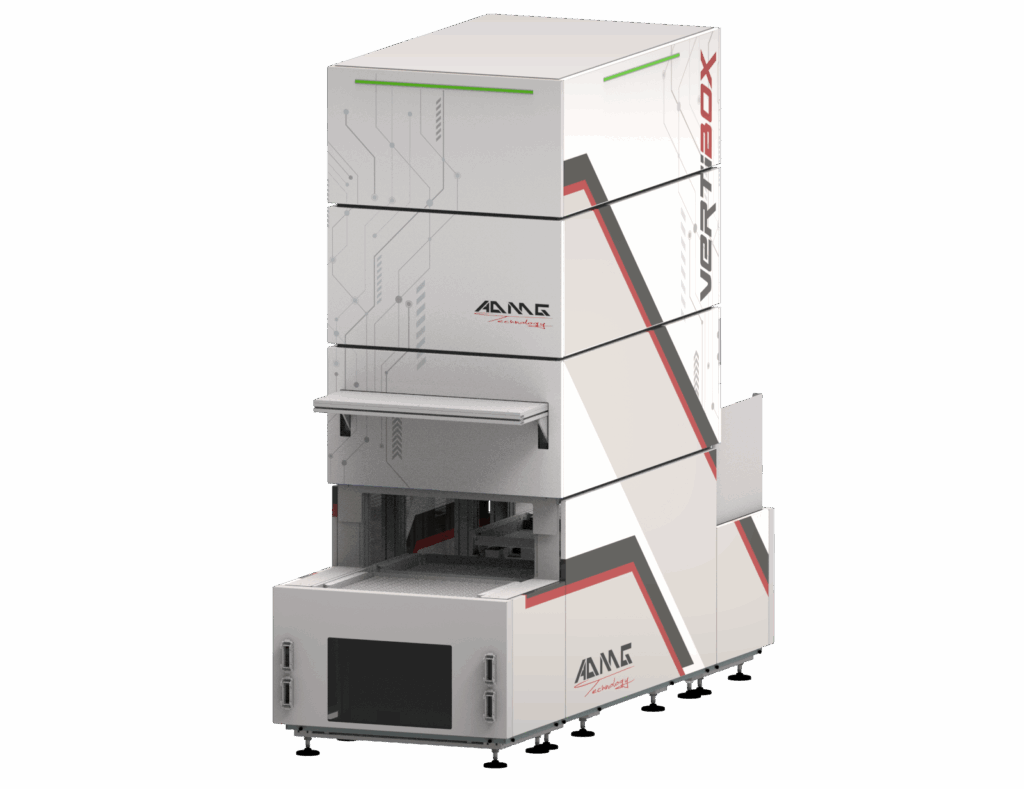

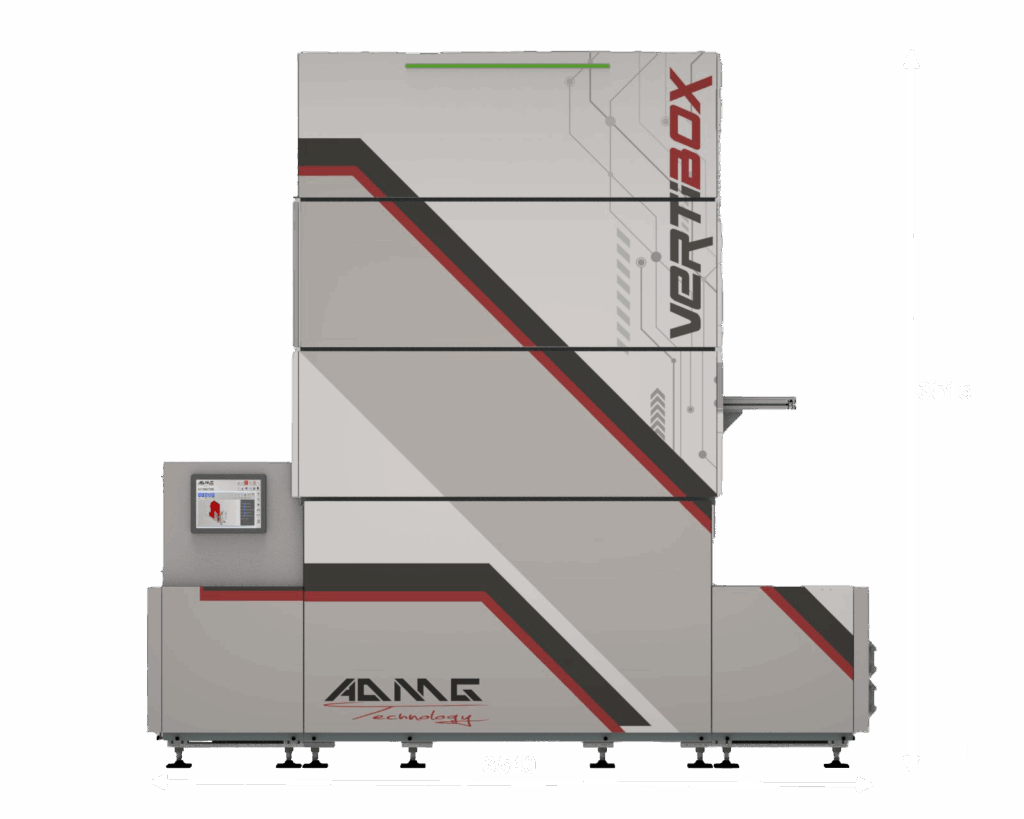

The structure of the vertical magazine is made of aluminum and has been designed to ensure safety, rigidity, and high loading capacity.

In the vertical magazine, there are 240 guides installed for supporting up to 56 trays. The guides are made of steel with plastic inserts for better sliding and to reduce noise during movement. The minimum distance of 65 mm between them, combined with the self-filling system, allows to maximize the occupied space.

The vertical magazine is equipped with a mobile platform located inside, in the center.

The platform is used to move the trays up and down and is equipped with a mechanism that allows the trays to be shifted to the right and left to the loading and unloading bays.

It is equipped with 4 braking pads for enhanced safety.

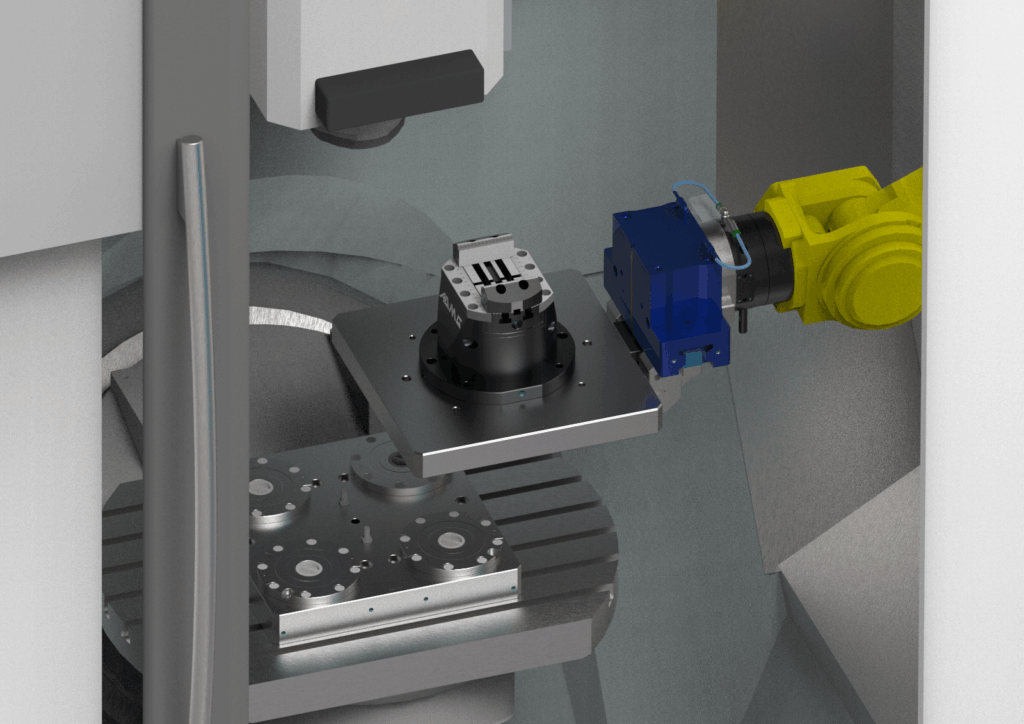

The magazine is equipped with a robot side bay where the trays are positioned by the platform for loading and unloading operations by the robot.

Moreover, on that side there is also a service shelf from where the robot picks up or deposits clamps and vices.

The magazine is equipped with an operator side bay (on the opposte side of Robot one) where the operator performs loading and unloading operations of parts onto trays.

The tray is easily removable for allowing a quick replacement.

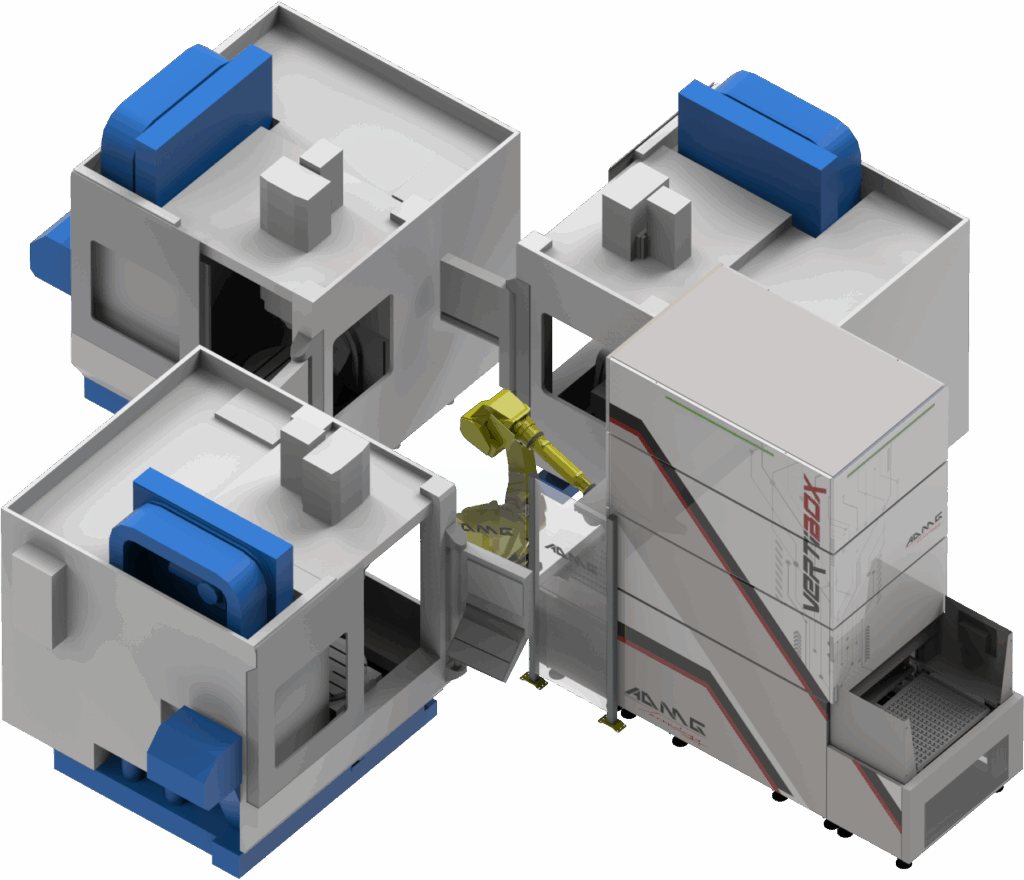

As standard equipment, RoboBox is offered with Robot Efort or Fanuc, both with loading capacity of 70 kgs. However, we can consider the installation of a different product based on Customer's needs.

The safety area of RoboBox, where the robot operates is resctricted by a modular system of panels.

The use of doors and walls is developed considering the customer's needs and the layout of the working area.

The standard version is supplied with aluminum panels and metal mesh (aluminum and polycarbonate panels are optional).

The electrical cabinet is located under the Robot loading bay while the robot controller is positioned at the bottom at the back to facilitate its use.

The control panel is located on the operator's bay side and is mounted on a telescopic arm so that it can be easily moved by the operator to the most optimal position.

Equipped with a 15.6" touchscreen monitor, it contains the ADMG supervisory software. It enables the interconnection of whole system, machines, robots, and magazine.

It is capable of managing the entire automated area in all its organization and production processes, minimizing the external intervention of the operator. Such a independence allows to reach up to days of machining in autonomy.

A system that fully meets the requirements of Industry 4.0.

The magazine has a maximum capacity of 56 drawers at a minimum distance in height of 65 mm. The maximum size accepted by the drawer is 300 mm in height.

Drawer size 600 x 800 x 250 kg.

Each drawer can be equipped with a jig designed by ADMG software for the correct placement of the workpieces.

Tools such as clamps or vices can also be housed in the drawers.

The magazine is equipped with a self-filling system.

Thanks to an electronic measuring system, the height of the tray and its incoming content is detected. Through a special algorithm, the position where the tray will be stored is determined to maximize the occupied space and avoid damage to the tray upon entering in case of exceeding the maximum allowed height.